Onsite services

IKP Service has developed a wide range of service concepts that are performed at the customer's site to maximize production time. This way, our customers do not have to interrupt their processes and production to identify and correct defects and root causes.

With over 40 years of experience at IKP, we come to the customer's site to identify the defects together, draw up repair plans and schedules, and take care of the repairs with experienced professionals. This allows the customer to focus on continuing their own business without interruption.

Onsite -palvelut

IKP Servicellä on kehitetty laaja valikoima palvelukonsepteja, jotka suoritetaan asiakkaan luona tuotantoajan maksimoimiseksi. Näin asiakkaamme ei tarvitse keskeyttää prosessejaan ja tuotantoaan vikojen ja juurisyiden tunnistamiseksi sekä niiden korjaamiseksi.

IKP:n yli 40 vuoden kokemuksella tulemme asiakkaan luokse Saitille tunnistamaan yhdessä viat, laadimme niiden korjaussuunnitelmat ja aikataulut sekä huolehdimme niiden korjauksista kokeneiden ammattilaisen kanssa. Näin asiakas saa keskittyä oman liiketoimintansa jatkamiseen keskeytyksettä.

Fault and root cause analyses

IKP Service Oy takes care of your business even after the new machines and equipment have been installed and the factory and equipment have been handed over to you. We offer you a full range of services from warranty service and maintenance to various fault and root cause analyses.

Together with our customer, we review the problems identified in the fault and root cause analyses and make suggestions for repair work based on these. Based on the analyses, we can provide you with information on the detailed work phases and what the repair costs will be.

alignment services

At IKP Service Oy you will find a comprehensive range of different alignment services for the alignment needs of electric motors, gearboxes, pumps, fans and various clutches.

We perform alignment and shim services professionally using SKF alignment equipment and provide the customer with a clear measurement report of the final result of the alignment service.

Installation and alignment services for larger factory complexes, both after new equipment installations and maintenance and repair shutdowns, are also a significant part of our On-Site service offering.

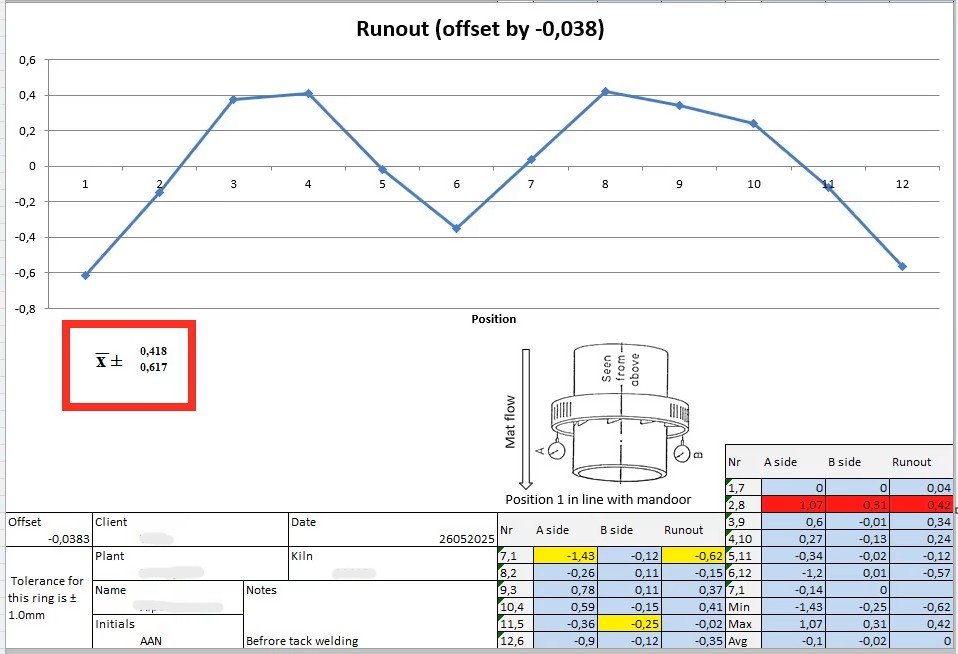

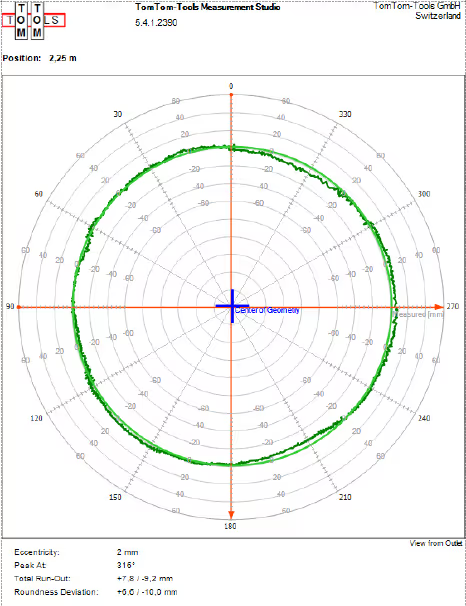

3D measurements

IKP Service Oy offers a comprehensive range of services related to the measurement of rotating equipment. These include baseline measurements of the roundness of various parts before work begins and inspection measurements upon handover of the work.

Examples include 3D measurements for various industrial furnaces, drums, pulpers and other rotating parts. We also provide various axial and parallelism measurements as well as alignment and height measurement services for the entire factory area.

Examples of baseline measurements for roundness and axial alignment

Straightening work on support frames and wheels

IKP Service offers its customers a comprehensive range of carrier frame and carrier wheel repair services and replacement services.

Our goal is to support our customer's production continuity by offering machining and grinding services for the support frames and wheels of various furnaces, drums, pulpers, and other rotating equipment.

There is no need to shut down or interrupt factory production, but we carry out the necessary renovations while production continues normally. In this way, our customer maximizes their production time and IKP takes care of the implementation of the work on a 24/7 basis, as agreed with the customer.

Repair welding of carrier frames and wheels is also part of IKP's service package.

welding & repair services

We offer our customers various repair welding services implemented using different welding methods as On-Site services.

We repair weld various carrier frames, carrier rollers, and other components and parts to repair cracks, splits, and other detected connection defects on site at the customer's site.

Any NDT inspections that may be performed on welding work can also be carried out through us thanks to our cooperation network.

Line and core drilling

IKP Service carries out a wide range of line and hole drilling work at the customer's site. These include, for example, the internal machining of various lugs in the same line. The targets may include, for example, various drilling of gear rims, machining of conveyor buckets, line drilling of buckets and platforms of heavy vehicles. We carry out surveys for the customer regarding the work on site, during which the method of implementation of the work is agreed upon.

Other repair work, such as repair welding, can also be carried out in connection with these re-machining operations.

contact us

Contact us – we will respond with iron-clad professionalism

Our operations consist of Iin Konepaja Oy, which specializes in the manufacture of steel products, and IKP Service Oy, which offers maintenance and repair services. Together, we form a versatile and competent partner for industrial needs – from individual jobs to larger projects.

It is important to us that the work is done flexibly, quickly and with high quality, but above all responsibly. We operate with a long-term perspective and invest in environmentally friendly choices throughout the production chain. We want to be part of building an industry that lasts and consumes less.

We are proud of our Finnishness and local roots, as our roots extend back to Ii in 1980. We know our industry, our customers, and the Arctic conditions – and we do our work with the precision and consideration that comes with it.

Sustainable industry is born from actions – contact us and let's start a collaboration that takes both business and the environment into account.

Sustainable industry is born from actions – contact us and let's start a collaboration that takes both business and the environment into account.